Galvanized sheet steel is, perhaps, one of the most important innovations of the modern world. It’s safe to say that, without galvanized sheet steel, the modern world wouldn’t even exist, and we would still be living in thatched roof buildings that are no more than 10 storeys high, driving down cobblestone roads on horse-drawn carts.

That might sound like an exaggeration, but it’s not. That’s because galvanized sheet steel is in pretty much every single modern convenience today, from construction and public works to pretty much every aspect of the automotive industry.

A Brief History of Steel Production:

The Bessemer Process was introduced in the late 1800’s and was crucial in the mass-production of steel beams for construction, giving rise to the age of the skyscraper. However, the predecessor of steel beams, the steel sheet, actually started way back in the early Renaissance, when scientist/poet/writer/artist/Tony Stark of that Era/engineer wunderkind Leonardo Da Vinci drew up sketches for a steel rolling mill that was advanced for their time. Over the centuries that followed, blacksmiths and other metal workers relied on these sketches to start perfecting metal rolling technology to create gold coins, brass plates, and pieces of armor, leading to the first industrial steel manufacturing plant in 1615. By the mid-1600’s, early metallurgists tried experimenting with different ways to purify different metals and create allows, leading to a surge of different techniques that gave rise to the study of metallurgy.

By the early 1760s, steel production was in full swing, thanks to the Industrial Revolution, which made producing steel faster, easier, and more reliable than when Leo Da V did it.

By the 20th century, scientists started experimenting with different types of chemical additives and innovative processes to make sheet steel stronger, more durable, more sustainable, more cost-effective, and much more flexible.

Galvanized Steel: The Superior Choice

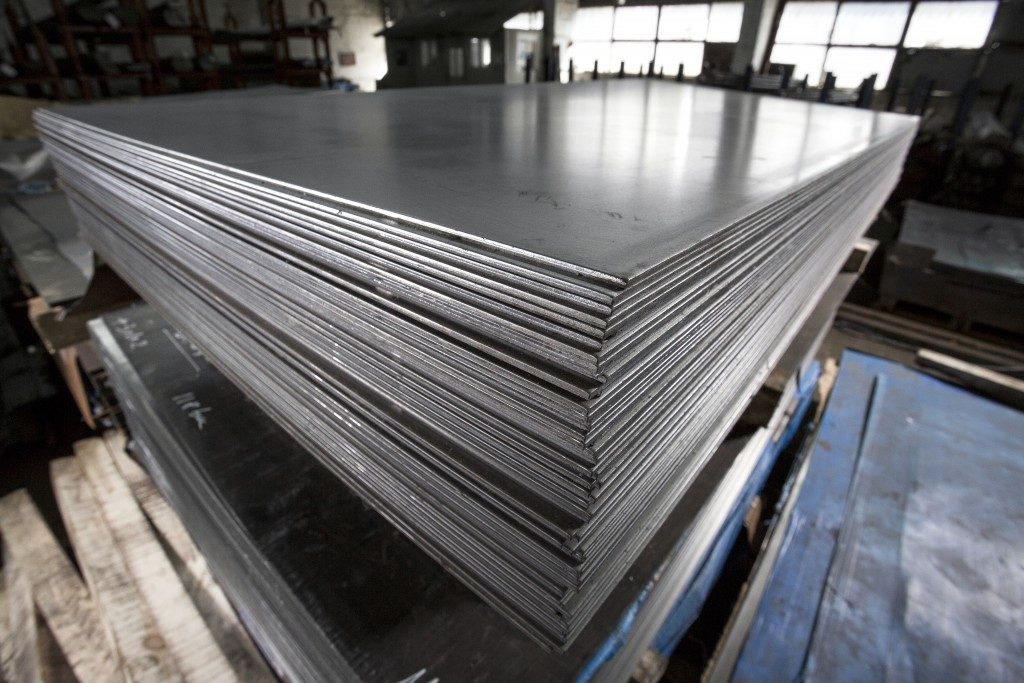

Over time, scientists created the process of galvanization, which is when a piece of metal (often steel or iron) is coated in a protective layer of zinc to prevent it from rusting. This is often applied to sheet metals. Sheet steel can be coated in many ways, so it has protection from corrosive agents and could improve its appearance. Formed as flat panels, galvanized steel sheet goes through galvanization in two ways. One is through electrogalvanized coating, which is applied at ambient temperature. This guarantees that the tensile properties of the base steel remain. The other is hot-dipped galvanizing, which is done at elevated temperatures. This changes the base steel properties.

There’s very little exaggeration when people say that galvanized sheet steel is the superior choice for all kinds of manufacturing purposes, whether it’s in constructing a high-rise or in mass-producing a car. It’s strong, sustainable, reliable, flexible, and the most cost-effective metal available to all mass producers.

Stronger Than Regular Steel

Galvanized steel is pretty much stronger than ungalvanized steel, mainly because the former has a protective layer that also acts as a sort-of augment that gives it better compressive strength and tensile strength. This is true for most galvanized steels, but sheet steel that has undergone electrogalvanization are particularly stronger.

But perhaps the strongest type of galvanization is a process called hot-dipped galvanization, which is when whole sheet steel is literally dipped into molten zinc, tempering the steel and bonding the zinc at a molecular level, turning it into one of the strongest materials known to man.

More Durable than Ungalvanized Metals

The process of galvanization not only makes the sheet steel stronger, it also makes it so much durable. In essence, the zinc covering pretty much protects the steel from pretty much every external factor possible, whether it’s extreme weather conditions, rapid and constant temperature shifts, impact, compression, and even stretching.

Galvanized sheet steel is also practically rust-free: zinc does not react to oxygen, which protects the stronger (albeit more fragile) steel underneath.

Whatever the condition galvanized sheet steel is in, it will last longer. The life expectancy is considerably longer even in the harshest environmental conditions, enduring areas or places that get a lot of sun, rain, or snow. In effect, you need not to keep on replacing the material.

Galvanized Steel is Sustainable

Since the start of the Industrial Revolution back in the early 1700s, the world’s appetite for steel has only grown, often to the detriment of the environment.

In fact, steel production is still one of the worst causes of environmental damage around the world, second only to the strip mining of rare earth materials and, of course, fossil fuel production.

However, by galvanizing sheet steel, producers are able to reduce the need for people to buy more steel, lessening the impact on the environment. That’s because galvanized steel is recyclable, making it one of the most sustainable industrial materials possible. The zinc coating, for instance, lengthens the sheet’s use so production of new sheets is greatly lessened. But, perhaps, one of the best things about galvanized sheet steel is its reusability. Because the zinc coating will practically be on the steel forever, scrap galvanized steel can be repurposed without having to worry about durability issues.

Cost-Effective Galvanized Steel

Sheet steel that is galvanized improves usability, allowing users to spend less. The longevity of galvanized sheet steel easily makes it the most efficient construction material to use. Most of the time too, galvanized sheets are cheaper in the market compared to sheets that underwent other forms of treatment. Other galvanized products that are heftier in terms of cost would still be a better choice as long term costs diminish through time.

Galvanized Steel is Flexible

Flexibility is another benefit that makes galvanized sheet steel worthy as a product. It can be used in many types of applications and is widely used as a structural component in the construction industry. In terms of users, both the residential and commercial sectors find the product a reliable product to their varied applications.

Sheet steel is a potent structural material in itself. When galvanized, it becomes a more sound and useful product.

The reasons above show why galvanized sheets are a market favorite. If you’re looking for a reliable material, then don’t hesitate to get this one.

Galvanized Steel: The King of Metals

With its unique properties — properties that help production and reuse galvanized sheet steel is a truly reliable material. For users, especially those in industrial settings, the product’s lifespan is predictable, allowing for few surprises in the course of time it is being used. When used in residential areas, its strength is ideal since it can hold the weight and tension of other materials that it joins or builds on. More so, this product uses raw materials that are not difficult to source out.